GATLINGTECH

H1001 Dry ice Cleaning Machine With 5 Nozzles For Carbon Mold Removal Industrial Factory

H1001 Dry ice Cleaning Machine With 5 Nozzles For Carbon Mold Removal Industrial Factory

📢 Looking for more details about our products? Contact us via WhatsApp to:

📢 Looking for more details about our products? Contact us via WhatsApp to:

☑️ Get product brochures

☑️ Schedule a live factory tour

☑️ Request a quote

☑️ Ask any questions

Click the button below and chat with us instantly!

H1001 Dry Ice Cleaning Machine

The H1001 is a high-performance dry ice cleaning machine designed for industrial applications requiring non-abrasive cleaning. This machine offers excellent performance for mold cleaning, parts cleaning, and carbon deposit removal. It has a dry ice capacity of 20KG and an output rate ranging from 0.3kg/min to 0.6kg/min, ensuring efficient cleaning of delicate surfaces without damage.

Key Specifications

- Voltage/Frequency: Custom-made

- Compressed Air Input Pressure: 0.6MPa - 0.8MPa adjustable

- Dry Ice Capacity: 20KG

- Dry Ice Output: 0.3kg/min - 0.6kg/min

- Particle Size: 3mm or less

- Compressed Air Input Flow: 2m³-4m³ (ensure 0.4MPa pressure after continuous operation)

Product Highlights

- Perfect for mold cleaning, parts cleaning, and carbon deposit removal

- Ideal for industrial applications that require non-abrasive cleaning

- Efficient dry ice output for effective cleaning without damaging surfaces

- Adjustable compressed air input for optimal performance

Included Accessories

- High-altitude air hose

- Low-temperature dry ice hose

- Anti-static cable

- Dry ice shovel

- Noise-canceling earmuffs

- Safety goggles and anti-static gloves

Quote Now

Pre-Quote

Contact us-

Shipping Origin:

Products are shipped from Jiangsu, China.

Lead Time:

For in-stock items, shipping usually takes 3–5 business days to dispatch.

Delivery Time:

International delivery typically takes 7–30 business days.

Shipping Costs:

Determined by product size, weight, and destination – we will include a quote in our reply.

-

Customization:

Customized products (with logos or special specs) are non-refundable and require a confirmed production time.

Returns & Warranty:

Returns for non-quality issues are currently not supported (including both customized and non-customized products). All items are covered by our warranty, so you can shop with confidence.

Customs Duties:

Import taxes and duties are the buyer’s responsibility.

Use Cases & Applications

-

Heat exchanger

The pain point before cleaning is fouling blockage hindering efficiency, while the effect after high-pressure cleaning is clear tubes restored to pristine condition.

-

Floor Degreasing

Stubborn oil stains create slippery hazards and unsightly surfaces, while the cleaning effect is a grease-free, safe, and visibly improved floor.

-

Equipment Cleaning

Heavy fouling and deposits severely impede operational efficiency, while the cleaning effect reveals clean surfaces ready for optimal performance.

-

Vehicle Cleaning

Accumulated grime and dirt obscure the vehicle's appearance and can cause damage, while the cleaning effect reveals a spotless, well-maintained, and visually appealing vehicle.

-

Farm Pottery Cleaning

Stubborn farm grime makes pottery dirty and unhygienic; cleaning restores cleanliness and appearance.

-

Mold Cleaning

Mold buildup hinders production efficiency and product quality; effective cleaning restores optimal performance and product integrity.

-

Moss Removal

Moss growth leads to slippery, damaged surfaces; cleaning effectively restores safety and structural integrity.

-

Radiator Fin Cleaning

Accumulated dust and debris on radiator fins reduce cooling efficiency, leading to overheating; thorough cleaning restores optimal heat dissipation and engine performance.

-

Paint Removal

Unwanted paint layers detract from appearance and hinder proper surface treatment; effective removal reveals a clean substrate ready for refinishing or other processes.

-

Building Facade Cleaning

Accumulated dirt, pollution, and biological growth mar building aesthetics and can cause structural damage; thorough cleaning restores visual appeal and preserves the building's integrity.

-

Mold Refurbishment

Accumulated residue and minor damage on molds hinder performance; high-pressure cleaning effectively removes buildup and prepares the surface for further restoration.

-

What Do You Need to Clean? Let Us Help!

Contact usNot sure which high-pressure washer suits your application? Contact us with your cleaning needs, and our experts will recommend the right machine and solution.

- - -

Email: [email protected]

Australia: +61 468 839 360

China: +86 139 8612 2400

Imessage: +61 468 839 360

WhatsApp: +61 468 839 360

Youtube: @GATLINGTECH

Why Choose GATLINGTECH?

We provide high-quality cleaning equipment with international certifications and global customer trust. Our modern production ensures reliability, sufficient inventory enables fast delivery, and comprehensive after-sales support gives you peace of mind.

GATLINGTECH

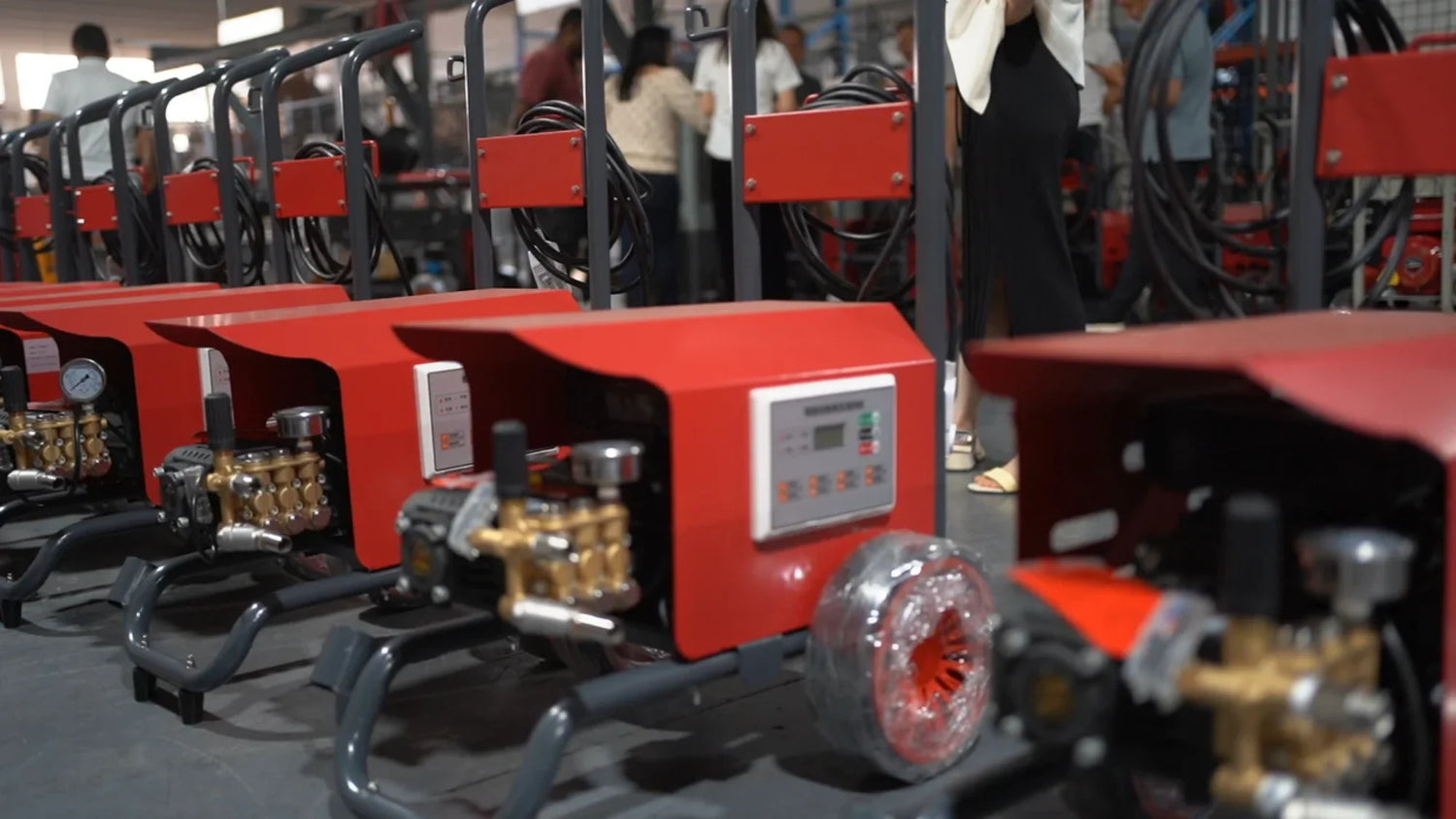

Manufacturing Strength

Equipped with advanced manufacturing facilities, our factory strictly follows quality management systems to ensure stable performance and reliable quality of each machine.

GATLINGTECH

Sufficient Inventory

With ample stock and an efficient logistics system, we ensure fast order processing and timely delivery of our equipment.

GATLINGTECH

Trusted by Global Clients

Our equipment is exported to Europe, Southeast Asia, and beyond, widely used in industries such as manufacturing, food processing, and industrial cleaning.

GATLINGTECH

Quality Assurance

Certified by CE, ISO, and other international standards, our products meet the highest industry requirements for safety and reliability.

GATLINGTECH

After-Sales Support

We offer technical support, remote guidance, and spare parts supply to ensure long-term and stable operation of your equipment.